Why High-Efficiency Motors Are the Future of Industrial Power

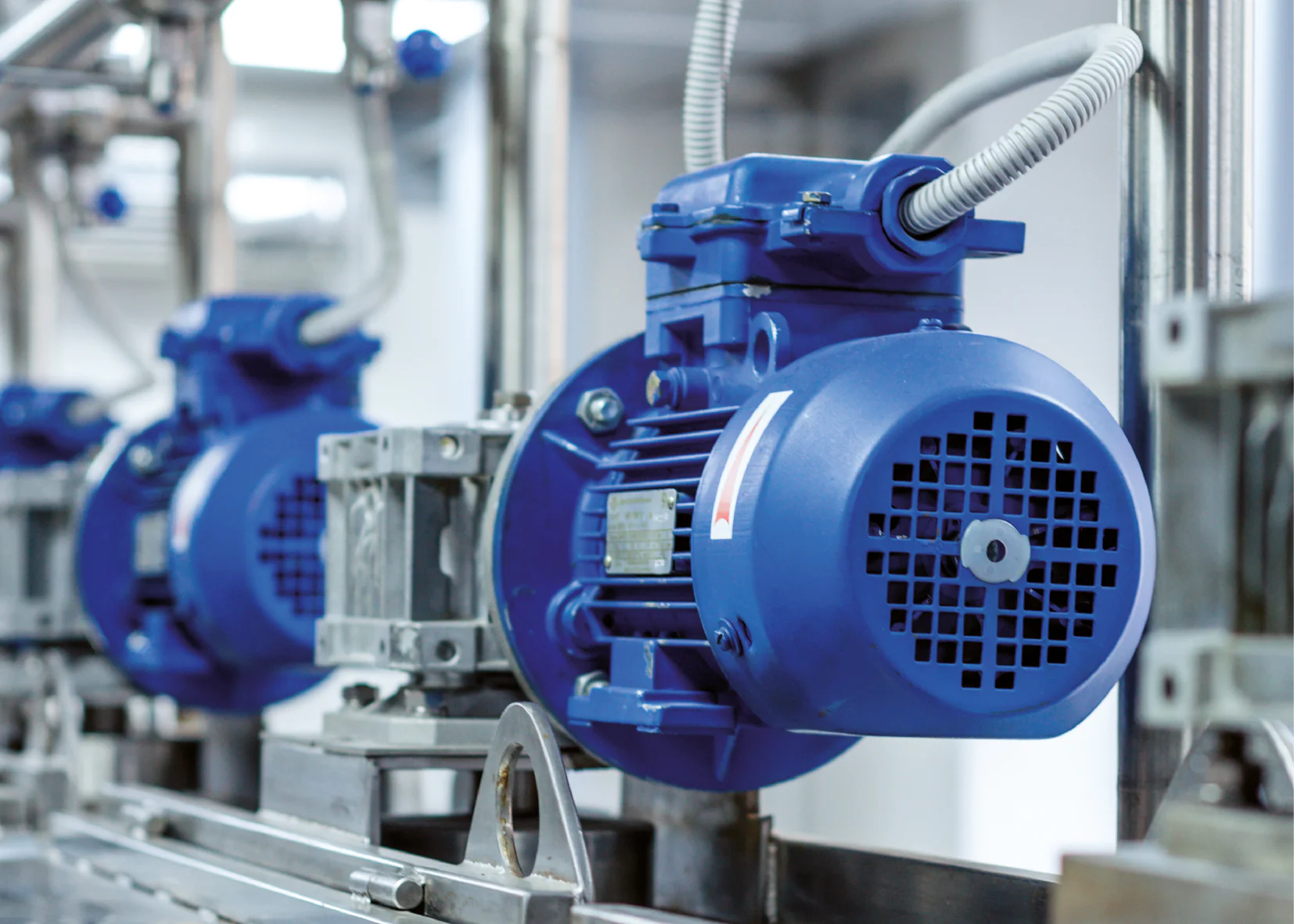

In today’s competitive and environmentally conscious world, high-efficiency motors have become a standard across industries. At GEXIN, we’ve developed a full range of energy-saving motors, such as the YE3 and YE4 series, designed to meet the growing demand for sustainable and cost-effective motor solutions.

The Cost of Inefficiency

Traditional motors waste energy in the form of heat and magnetic loss. In high-volume operations, even small inefficiencies result in substantial energy bills. GEXIN’s high-efficiency motors improve power factor, reduce thermal stress, and extend equipment lifespan.

Benefits of High-Efficiency Motors

-

Energy Savings: Up to 20% less power consumption compared to standard motors.

-

Reduced Carbon Emissions: Supporting your ESG goals and regulatory compliance.

-

Lower Maintenance: Premium bearings, better insulation, and balanced rotors mean fewer breakdowns.

-

Faster ROI: Initial investment in a high-efficiency motor is quickly recovered via electricity savings.

Real-World Applications

Our YE3 motors are widely used in production lines, air compressors, and HVAC systems, where continuous operation is needed. For variable-speed systems, YVF2 frequency motors provide further efficiency by adjusting motor speed to the load requirement.

GEXIN’s Technology Edge

-

Fully automatic winding and rotor balancing.

-

Temperature and vibration detection systems during testing.

-

Advanced stator core lamination for reduced loss.

Environmental Commitment

By switching to GEXIN’s high-efficiency motors, our global clients have collectively saved millions of kWh annually — contributing to a greener planet and leaner operations.

Final Thoughts

Energy-efficient motors are no longer optional — they’re essential. With GEXIN, you gain access to world-class engineering, consistent quality, and a future-ready product portfolio. Let’s drive sustainability together.